The Evolution of Shower Door Hardware

The bathroom has undergone a remarkable transformation over the past century. What was once a purely functional space has evolved into a personal sanctuary—a place for relaxation and rejuvenation. At the center of this evolution stands the modern shower enclosure, with stainless steel shower door hardware emerging as the backbone of contemporary bathroom design.

Back in the 1950s and 60s, shower enclosures featured bulky frames made primarily from aluminum with plastic components that deteriorated quickly in the moisture-rich environment. The hardware was often an afterthought—purely functional elements hidden behind thick metal frames. By the 1980s, as bathroom spaces began to expand in homes, frameless shower doors started gaining popularity, bringing hardware elements into the spotlight.

During a renovation project I undertook in 2019, I discovered vintage shower hardware in a client’s 1970s home—heavy chrome-plated brass that had corroded substantially despite its substantial build. It illustrated perfectly how far we’ve come in material science.

The transition to stainless steel as the premier material for shower door hardware wasn’t just about aesthetics. Craig Foster, a materials engineer specializing in bathroom fixtures, explained to me at a recent trade show that “the molecular structure of properly manufactured stainless steel creates a unique self-healing property—a passive layer that continuously protects against corrosion, making it ideal for wet environments.” This scientific advancement fundamentally changed what was possible in shower design.

Today’s stainless steel shower door hardware combines sophisticated engineering with minimalist design principles. The exposed hinges, handles, and support bars have become statement pieces in their own right. Modern hardware doesn’t just support the door—it enhances the entire bathroom’s design language while providing unparalleled performance in demanding conditions.

Why Stainless Steel Dominates Shower Hardware

When selecting materials for shower door hardware, few options can match stainless steel’s comprehensive benefits. The dominance of stainless steel in this application stems from a perfect convergence of practical and aesthetic advantages.

The fundamental property that makes stainless steel exceptional for bathroom applications is its remarkable corrosion resistance. Unlike standard steel or even brass, quality stainless steel contains at least 10.5% chromium, which forms an invisible protective layer when exposed to oxygen. This chromium oxide barrier continuously renews itself when damaged, providing long-term protection against moisture and common bathroom cleaning chemicals.

I’ve examined shower door hardware installed over a decade ago that looks virtually identical to new pieces—a testament to this material’s longevity. During a bathroom renovation project in a coastal home, the original brass hardware had deteriorated significantly after just four years due to salt air, while neighboring homes with stainless components showed no such issues.

From an aesthetic perspective, stainless steel offers unmatched versatility. Jane Richardson, an interior designer with over 20 years of experience in bathroom spaces, notes that “stainless steel hardware serves as a chameleon in design—it can disappear into the background in minimalist spaces or become a bold statement in more dramatic bathrooms, depending on the specific finish and style selected.”

The material also presents significant environmental and health advantages. Most stainless steel shower door hardware contains recycled content, sometimes exceeding 60% according to industry data. Additionally, stainless steel is non-porous, making it inherently hygienic and resistant to bacterial growth—a critical consideration for wet bathroom environments.

For those concerned with indoor air quality, stainless steel emits no VOCs (volatile organic compounds), unlike some coated hardware alternatives. This makes it an ideal choice for individuals with chemical sensitivities or those simply seeking healthier living spaces.

The durability factor cannot be overstated. In commercial settings where shower facilities see heavy use, facility managers consistently report that stainless steel hardware outlasts alternatives by significant margins, often 3-5 times longer than conventional materials. This durability translates to residential applications as well, where the initial investment yields long-term value.

That said, not all stainless steel is created equal. The distinction between grade 304 stainless steel (the most common) and marine-grade 316 stainless steel becomes particularly important in extremely humid environments or coastal locations. The addition of molybdenum in 316 stainless steel provides enhanced protection against chloride corrosion—something to consider for oceanfront properties or homes with saltwater pools.

Essential Components of Stainless Steel Shower Door Systems

Creating a functional, beautiful shower enclosure requires understanding the critical components that comprise a complete stainless steel shower door system. Each element serves both practical and aesthetic purposes, working together as an integrated whole while addressing specific functional requirements.

Hinges and Pivots: The Foundation of Movement

Hinges represent perhaps the most engineered component in the entire system. They must support substantial weight—often 80-100 pounds of tempered glass—while enabling smooth operation and maintaining precise alignment over thousands of cycles. The distinction between wall-mounted hinges and glass-to-glass hinges is crucial when planning your shower configuration.

Wall-mounted hinges anchor directly to the wall structure, typically requiring reinforcement behind the wall surface. Glass-to-glass hinges, meanwhile, connect two panels of glass at precise angles, allowing for more creative enclosure designs. During a recent installation, I encountered a situation where the wall lacked adequate support for heavy wall-mounted hinges—switching to a header-supported system with lighter pivots solved the issue without compromising design intent.

Pivot hinges differ from standard hinges by allowing the door to swing in both directions. They’re particularly useful in smaller bathrooms where space optimization is essential. The engineering behind modern stainless steel pivot systems has advanced significantly, with some incorporating self-centering mechanisms that gently return the door to the closed position.

The weight capacity ratings of hinges vary widely, typically ranging from 60-120 pounds. Robert Chen, a glass shower system engineer, emphasizes that “with hinges, there’s no place for compromise—undersized hinges eventually lead to alignment issues, while oversized units waste resources and can look disproportionate. Precise matching of hinge capacity to door specifications is essential.”

Handles and Pulls: The Human Interface

Handles provide both functional access and serve as prominent design elements. The ergonomics of shower handles matter significantly—they’re used with wet hands and should provide secure gripping surfaces. Back-to-back handles connected through the glass create a clean look while providing operation from both sides.

I’ve noticed a trend toward minimalist finger pulls that barely interrupt the glass surface, creating an almost invisible hardware presence. These work beautifully in contemporary spaces but sacrifice some ergonomic advantages of larger handles.

The handle-to-hinge relationship requires careful consideration. These components should share design language and finishing details. Mismatched elements can disrupt the visual cohesion of the entire shower enclosure. The distance between handles and hinges also impacts the mechanical advantage when opening the door—affecting how heavy the door feels during operation.

Support Systems: Creating Stability

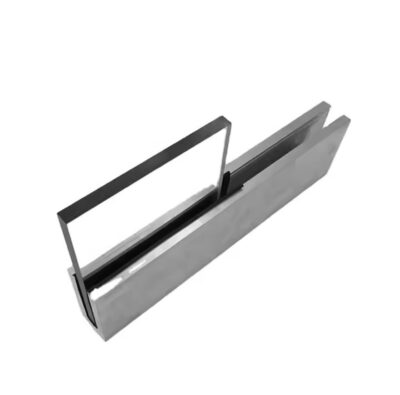

Support bars, channels, and clips form the infrastructure that stabilizes the entire shower enclosure. A frameless shower door without proper support risks dangerous movement or glass breakage. U-channels along the bottom edge provide consistent support while header bars across the top create stability for taller enclosures.

Support clips, sometimes called clamps, secure fixed panels to adjacent walls. These components distribute pressure evenly across the glass edge, preventing stress points that could lead to failure. Modern clip designs have significantly reduced in size while maintaining structural integrity.

The engineering tolerances of quality stainless steel support systems accommodate the natural settlement that occurs in most buildings. A shower installation I completed in a newly constructed home incorporated adjustable support clips that allowed for fine-tuning as the structure settled during its first year—preventing glass strain without requiring reinstallation.

Seals and Sweeps: The Waterproofing Elements

Though often overlooked, seals and sweeps play a crucial role in containing water and preventing leakage. Clear vinyl seals between glass panels create water barriers while maintaining visual transparency. Bottom door sweeps direct water back into the shower area rather than onto the bathroom floor.

I’ve found that stainless steel hardware systems that integrate their sealing elements seamlessly perform better over time than those with add-on seals. The material interface between stainless components and vinyl or silicone seals requires thoughtful engineering to prevent gaps that could lead to water damage.

This comprehensive system of components works together to create a shower enclosure that balances aesthetics, functionality, and safety. The quality of stainless steel used throughout these components determines not just their appearance but their long-term performance in the demanding bathroom environment.

| Component Type | Function | Common Variations | Typical Weight Capacity |

|---|---|---|---|

| Wall-Mount Hinges | Connect door to wall | Standard, Offset, Self-closing | 80-120 lbs per pair |

| Glass-to-Glass Hinges | Join glass panels | 90°, 135°, 180° configurations | 70-100 lbs per pair |

| Handles/Pulls | Door operation | Back-to-back, Single-sided, Knobs, Towel bar combinations | N/A |

| Support Bars | Stabilize fixed panels | Wall-to-glass, Glass-to-glass, Ceiling-to-glass | 80-150 lbs depending on length |

| U-Channels | Bottom edge support | Full length, Partial segments, Clear seal inserts | Varies by glass thickness |

| Clamps/Clips | Wall mounting for fixed panels | Square, Rounded, Beveled edges | 50-80 lbs per clip |

Technical Considerations for Selection and Installation

Selecting and installing stainless steel shower hardware requires careful technical planning to ensure long-term performance. The decisions made during the planning phase significantly impact not just the appearance but the structural integrity and functionality of the entire shower system.

Glass thickness compatibility stands as perhaps the most fundamental consideration. Most residential shower doors utilize either 3/8″ (10mm) or 1/2″ (12mm) tempered glass. Hardware designed for one thickness generally won’t work properly with the other. During consultation with clients, I’ve often had to explain why the sleek hardware they admired in a design magazine won’t work with the thicker glass required by their local building code—a frustrating but necessary reality check.

Weight capacity calculations must account for the complete door assembly. A standard 36″ × 72″ shower door in 1/2″ glass weighs approximately 75-85 pounds before hardware. As Thomas Welch, a glass installation specialist with 25 years of experience, told me, “I’ve seen beautiful hinges fail catastrophically because someone selected them based on aesthetics rather than load ratings. There’s simply no compromise possible when it comes to weight capacity.”

The structural integrity of mounting surfaces demands equal attention. Stainless steel hardware typically anchors to wall studs or blocking rather than just drywall or tile. During a recent renovation in an older home, we discovered inadequate wall structure behind the planned hinge locations, necessitating opening the wall to install proper blocking—an unexpected but essential step.

This table illustrates typical hardware requirements for different door configurations:

| Door Configuration | Glass Thickness | Recommended Hinge Type | Number of Hinges | Support Bar Requirement |

|---|---|---|---|---|

| Standard Swing (≤30″ wide) | 3/8″ (10mm) | Wall mount | 2 | Optional |

| Standard Swing (≤30″ wide) | 1/2″ (12mm) | Wall mount | 2 | Optional |

| Wide Swing (>30″ wide) | 3/8″ (10mm) | Wall mount | 3 | Recommended |

| Wide Swing (>30″ wide) | 1/2″ (12mm) | Wall mount | 2-3 | Required |

| Pivot Door | 3/8″ or 1/2″ | Pivot system | 2 pivots | Required for panels >30″ |

| Heavy Custom Door | 1/2″ (12mm) | Heavy duty | 3 | Required with header |

Clearance and space planning present another critical dimension. Shower doors require adequate swing space, typically the full width of the door plus 2-3 inches. In confined bathrooms, sliding hardware systems can resolve clearance issues, though they introduce different structural requirements. I once redesigned a shower entry to utilize an offset pivot hinge that reduced the needed clearance by nearly 5 inches—saving a costly bathroom reconfiguration.

Water management integration ensures that hardware placement complements rather than compromises waterproofing. Hardware should never bridge waterproofing membranes without appropriate sealing methods. Modern installation practices typically include silicone isolation between metal hardware and tile surfaces to prevent water migration.

The technical precision required during installation cannot be overstated. Most quality stainless steel hardware allows for minimal adjustment—typically just 1/8″ in any direction. This demands extremely accurate templating and preparation. The tools required for proper installation go well beyond basic home toolkits, including specialized glass drilling equipment, high-precision levels, and custom torque wrenches calibrated for specific hardware.

One often-overlooked technical consideration is thermal expansion. Glass and metal expand and contract at different rates with temperature changes. Quality hardware systems incorporate subtle design elements to accommodate these differences without stressing the glass. In a steam shower I installed last year, we specifically selected hardware designed with enhanced expansion tolerances to handle the extreme temperature variations.

Finishes and Design Options in Modern Stainless Steel Hardware

The finish applied to stainless steel shower door hardware significantly influences both its appearance and performance characteristics. Modern manufacturing processes offer a diverse palette of options beyond traditional polished or brushed surfaces, enabling precise design coordination across bathroom elements.

Brushed stainless steel (sometimes called satin finish) remains the most popular choice for several practical reasons. Its linear texture masks water spots and fingerprints while providing a sophisticated, understated appearance. During a recent design consultation, my client initially preferred polished hardware until I demonstrated how quickly water spots appeared on the sample—the brushed finish immediately became the obvious choice for their active household.

Polished stainless steel creates a mirror-like reflective surface that maximizes light reflection and creates a sense of luxury. Though requiring more frequent cleaning, its brilliant appearance makes a striking statement in formal bathroom designs. The optical brightening effect can make smaller shower enclosures appear more spacious.

Beyond these standard options, specialty finishes have expanded dramatically in recent years. Black stainless steel has gained significant popularity, created through a process called physical vapor deposition (PVD) that bonds color molecules to the stainless surface rather than simply coating it. This technology produces remarkably durable colored finishes that resist scratching and maintain their appearance for years.

Jennifer Liu, a bathroom designer specializing in luxury properties, notes that “the emergence of consistent black and gold stainless finishes has revolutionized contemporary bathroom design, allowing hardware to become a genuine design element rather than just a functional necessity.” Other popular PVD options include champagne bronze, oil-rubbed bronze, and graphite—all with the underlying performance benefits of stainless steel.

The visual weight of hardware varies dramatically across design styles. Minimalist hardware with clean lines and reduced bulk creates an almost weightless appearance where glass seems to float. In contrast, industrial-inspired designs emphasize hardware presence with substantial proportions and visible fastening elements. The choice between these approaches should complement the overall design language of the bathroom space.

Mixing stainless steel with complementary materials has emerged as a sophisticated design strategy. Shower systems that combine stainless components with wood, stone, or composite elements create textural contrast while maintaining performance integrity. I worked with a client who integrated teak handles with stainless hinges in a Japanese-inspired bathroom—the warmth of wood against the cool stainless created a sensory balance that elevated the entire space.

When selecting finishes, consistency across all hardware elements creates a cohesive appearance. This extends beyond the shower to faucets, towel bars, and other bathroom accessories. Major manufacturers have recognized this need by developing comprehensive bathroom hardware collections with matching finishes across all elements. The investment in coordinated components pays visual dividends through a harmonious, thoughtfully designed space.

Maintenance and Longevity of Stainless Steel Shower Elements

While stainless steel shower door hardware offers exceptional durability, its longevity depends significantly on proper maintenance and understanding its performance characteristics in bathroom environments. With appropriate care, quality stainless components can maintain both function and appearance for decades.

The fundamental maintenance principle for stainless steel in shower environments is regular cleaning to prevent mineral buildup. Hard water deposits can eventually etch even quality stainless if allowed to accumulate. After installing high-end shower systems in numerous homes, I’ve observed a direct correlation between cleaning frequency and hardware appearance years later.

Different finishes require specific cleaning approaches:

For brushed/satin finishes, clean in the direction of the grain using mild soap and water, followed by thorough rinsing and drying. Avoid abrasive cleaners that can create inconsistent scratch patterns visible in certain lighting.

Polished finishes show water spots more readily but clean easily with microfiber cloths and dedicated stainless cleaners. I’ve found that applying a silicone-free stainless protectant twice yearly helps maintain the mirror finish with less frequent cleaning.

For PVD-colored finishes (black, gold, bronze), avoid ammonia-based cleaners that can potentially damage the colored layer over time. Mild soap solutions and specialized PVD-safe cleaners provide effective maintenance without risking finish degradation.

Preventing corrosion in stainless steel hardware primarily involves avoiding certain environmental exposures. Despite common misconceptions, not all stainless steel is equally corrosion-resistant. Regular 304-grade stainless can potentially develop surface corrosion in chlorine-rich environments or coastal locations with salt spray. For these situations, marine-grade 316 stainless offers superior protection.

I learned this distinction firsthand when hardware in a pool house bathroom developed surface spotting within a year of installation. The chlorine-heavy environment exceeded the corrosion resistance of the standard 304 stainless steel components. Replacing them with 316-grade hardware resolved the issue permanently—an expensive lesson in material selection.

Hardware movement components benefit from occasional lubrication with appropriate products. Silicone-based lubricants work well for hinge mechanisms without attracting dirt or degrading seals. Petroleum-based products should be avoided as they can damage rubber and plastic components within the hardware system.

Seals and sweeps typically require replacement before the stainless components show significant wear. These vinyl or silicone elements generally last 3-5 years before hardening or losing effectiveness. When replacing these elements, inspecting the stainless hardware for any adjustment needs ensures continued optimal performance.

The long-term maintenance outlook for quality stainless steel shower hardware is remarkably favorable. Professional shower installers report that well-maintained stainless components typically outlast the initial glass installation and often remain serviceable through multiple bathroom renovations. This longevity represents both environmental and financial advantages over time.

Cost Analysis and Value Considerations

The investment in stainless steel shower door hardware spans a considerable range, influenced by quality, design complexity, and finishing details. Understanding this spectrum helps balance initial costs against long-term value when planning a shower installation or renovation.

At the entry level, basic stainless steel shower hardware packages for standard-sized doors start around $200-300. These typically include fundamental hinges, handles, and minimal support components in standard finishes. While functional, these budget options often use lighter-gauge materials and simpler manufacturing processes that may limit long-term performance.

Mid-range hardware packages ($400-800) incorporate thicker materials, more precise manufacturing tolerances, and better internal components like sealed bearings and higher-grade fasteners. This tier typically represents the optimal balance between cost and long-term performance for most residential applications.

Premium hardware systems ($800-1500+) feature exceptional engineering, exclusive designs, and specialty finishes. These high-end components often include sophisticated features like soft-close mechanisms, adjustable mounting systems, and proprietary finishes with enhanced durability. For custom shower designs with oversize doors or unique configurations, these premium components may be necessary rather than optional.

Beyond the hardware itself, installation costs vary significantly based on complexity. Simple door installations with standard hardware might require 3-4 hours of professional labor, while complex enclosures with multiple panels and specialized hardware can represent 2-3 days of skilled installation time. This labor component often exceeds the hardware cost—reinforcing the importance of selecting components that install efficiently.

When evaluating value, I encourage clients to consider the complete lifecycle cost rather than just initial investment. Jennifer Travers, a real estate appraiser specializing in luxury properties, shared an interesting perspective: “In upscale homes, quality bath fixtures return approximately 85-90% of their cost at sale, compared to only 65-70% for basic fixtures. Buyers recognize and value the difference.” This resale consideration can justify investing in higher-quality components, particularly in homes that may be sold within 5-10 years.

The sustainability equation also favors quality stainless steel hardware. Premium components typically contain higher percentages of recycled material (often 60%+ versus 25-30% in budget options) and remain serviceable for decades rather than years. This extended service life distributes the environmental impact of manufacturing over a much longer period, reducing the overall resource consumption.

For those working with tight budgets, strategic allocation of resources can maximize impact. Focusing on critical structural components (hinges and support systems) while economizing on less stressed elements (handles and accessories) creates a solid foundation that can be aesthetically upgraded later if desired.

In my experience with hundreds of shower installations, the hardware tier selection should align with the overall project investment and expected longevity. For primary bathrooms in homes where occupants plan extended residence, premium hardware delivers genuine value through superior daily experience and reduced replacement needs. For secondary bathrooms or shorter-term housing, mid-range components typically provide the most favorable cost-benefit ratio.

Future Innovations in Stainless Steel Shower Hardware

The evolution of stainless steel shower door hardware continues at a remarkable pace, with emerging technologies and design concepts reshaping possibilities for future bathroom environments. These innovations address longstanding challenges while introducing new capabilities previously unavailable in traditional systems.

Smart integration represents perhaps the most transformative frontier in shower hardware development. Early explorations include humidity-sensing hinges that adjust closure tension based on steam levels and electronically-controlled privacy glass that changes from transparent to opaque via hardware-embedded controls. While working on a high-end bathroom renovation last year, I spoke with a manufacturer’s representative who revealed prototypes of touch-sensitive shower handles that can control water temperature and flow through the same hardware used to open the door—effectively consolidating bathroom controls.

Sustainability advancements are redefining manufacturing processes for stainless steel components. New development in metal forming techniques have reduced energy requirements by approximately 30% compared to traditional methods, while maintaining or improving structural integrity. Material innovations include stainless steel alloys with enhanced corrosion resistance that use reduced quantities of nickel and other limited resources.

Martin Hoffman, a metallurgist specializing in architectural metals, explained during a recent industry conference that “the next generation of stainless alloys aims for equivalent performance with significantly reduced cobalt and nickel content—both facing supply challenges as battery technology demands increase.” These material science advances promise more environmentally responsible hardware with uncompromised performance.

Design trends point toward even greater minimalism in visible hardware. The aesthetic trajectory favors nearly invisible mounting systems where glass appears to float without apparent support. This design direction requires sophisticated engineering to conceal structural elements while maintaining safety and stability. Prototypes I’ve seen demonstrate doors operating on completely concealed hinge mechanisms embedded within glass edges—eliminating visible hardware entirely.

The customization landscape is expanding through advanced manufacturing technologies. Digital modeling coupled with precision CNC manufacturing now enables hardware customized to specific shower dimensions and user preferences. This transition from standardized to personalized components improves both fit and function while reducing installation challenges. Custom hardware elements once requiring weeks of specialized fabrication can now be produced quickly through parametric design systems.

Health-conscious innovations address growing interest in hygienic bathroom environments. Antimicrobial stainless steel formulations incorporate copper ions that actively inhibit bacterial growth on hardware surfaces. These specialized alloys maintain traditional stainless appearance while providing continuous sanitizing action—particularly valuable for multigenerational households or individuals with compromised immunity.

The accessibility frontier shows promising developments in inclusive design that elegantly accommodates diverse abilities. New hardware systems incorporate subtle support elements that maintain clean aesthetics while providing enhanced stability for users with mobility challenges. These thoughtfully engineered components advance universal design principles without institutional appearance.

As we look toward future bathroom environments, stainless steel hardware will likely continue its evolution from purely functional elements to sophisticated systems that enhance comfort, sustainability, and wellness while maintaining timeless aesthetic appeal.

Choosing the Right Hardware for Your Shower Project

After exploring the comprehensive world of stainless steel shower door hardware, the practical question remains: how do you select the optimal components for your specific project? The decision framework involves balancing technical requirements, aesthetic preferences, and practical considerations.

Start with an honest assessment of your bathroom’s usage patterns. A master bath used daily requires different hardware specifications than a guest bath used occasionally. During consultations, I ask clients about household members, their height and strength variations, and any mobility considerations that might influence hardware selection. These human factors significantly impact appropriate handle positioning, door weight, and opening force requirements.

The architectural context establishes important parameters. Wall construction determines appropriate mounting hardware—with concrete or block walls requiring different anchoring systems than standard stud walls. Ceiling height influences the need for support bars or headers. The available space for door swing affects hinge selection, potentially indicating pivot or sliding systems for tight spaces.

Budget realities inevitably influence hardware decisions, but I’ve found focusing on quality tiers rather than individual component prices leads to better outcomes. E-Sang and other reputable manufacturers typically offer good-better-best options within cohesive design families. This approach enables strategic investment in critical structural components while economizing on less stressed elements if necessary.

Installation considerations should factor prominently in hardware selection. Components with adjustment capabilities accommodate the inevitable imperfections in wall structures and glass fabrication. Hinges with horizontal and vertical adjustment mechanisms simplify installation and enable fine-tuning if settlement occurs later. Systems designed as integrated packages generally install more efficiently than individually sourced components.

Future maintenance requirements deserve attention during selection. Components with accessible lubrication points and replaceable wear items maintain performance longer. Hardware designed for complete disassembly allows for thorough cleaning or part replacement without removing the entire door. These serviceability features extend functional lifespan significantly.

The decision between stock versus custom hardware involves tradeoffs. Standard components offer cost advantages and immediate availability, while custom hardware provides precise aesthetic and functional matching to specific project requirements. For unique shower configurations or distinctive design visions, the investment in custom components often justifies the additional cost and lead time.

Regional climate factors influence appropriate hardware specifications. Coastal environments benefit from marine-grade 316 stainless steel, while standard 304 stainless suffices for most inland applications. In tropical climates with sustained high humidity, hardware with enhanced water-shedding designs prevents mineral accumulation. These environmental considerations affect long-term performance dramatically.

When selecting hardware finishes, consider the complete bathroom context. Hardware elements should coordinate with faucets, lighting fixtures, and accessories to create visual cohesion. The most successful bathrooms implement a consistent finish strategy throughout the space, though intentional contrast can create striking design statements when thoughtfully executed.

Ultimately, quality stainless steel shower door hardware represents an investment in daily experience. The tactile quality of door operation, the solid secure feeling of properly specified hinges, and the visual harmony of well-designed components contribute significantly to bathroom enjoyment. By considering both technical requirements and experiential factors, you can select hardware that performs flawlessly while enhancing the overall bathroom environment.

Frequently Asked Questions About Stainless Steel Shower Door Hardware

Q: What are the benefits of using stainless steel for shower door hardware?

A: Stainless steel shower door hardware offers several benefits, including its corrosion-resistant properties, which are crucial in the damp bathroom environment. It is durable and requires minimal maintenance, making it ideal for long-term use. Additionally, stainless steel provides a sleek, modern aesthetic that complements various bathroom designs.

Q: What types of stainless steel shower door hardware are available?

A: Stainless steel shower door hardware includes a range of components such as door handles, hinges, roller systems, and seal strips. These components are designed to be durable and resistant to rust, ensuring they remain functional and visually appealing over time.

Q: Can I install stainless steel shower door hardware myself?

A: Installing stainless steel shower door hardware can often be done by someone skilled in DIY projects. However, it’s important to follow the manufacturer’s instructions carefully. If unsure, it’s advisable to seek professional assistance to ensure proper installation and secure attachment.

Q: How do I maintain stainless steel shower door hardware?

A: Maintaining stainless steel shower door hardware is relatively straightforward:

- Regular Cleaning: Use a mild soap solution and a soft cloth to remove dirt.

- Avoid Harsh Chemicals: Refrain from using abrasive cleaners that can damage the finish.

- Lubricate Moving Parts: Apply silicone-based lubricants for smooth operation.

This will help preserve its shine and functionality.

Q: Is stainless steel shower door hardware compatible with all types of shower doors?

A: Stainless steel hardware is versatile and can be adapted to fit various shower door configurations, including frameless and semi-frameless options. However, ensuring compatibility with specific door thicknesses and types is essential for a proper fit. It’s best to consult the manufacturer for specific compatibility information.

Q: How does stainless steel compare to other materials for shower door hardware?

A: Compared to materials like brass or aluminum, stainless steel offers superior corrosion resistance and durability, which are critical in humid bathroom environments. While brass provides a luxurious look and aluminum is often lighter and more budget-friendly, stainless steel is generally preferred for its ability to withstand moisture without rusting.